The Challenge

The new CUF Tejo hospital in Lisbon was from its early stages a highly complex project that required a team with sound technical experience and a response based on innovative procedures. Our performance had to consider not only the size of the project, but also the fact that we were working within a highly competitive sector with very demanding requirements.

Size and location

More than 75,000 m² of gross built area in a sensitive location. In the heart of the Alcântara Valley, next to Lisbon Riverfront, the geomorphology of the land and the proximity to the river presented the first challenges to our team. With a total of 10 floors, 4 of which to be built below ground level, that substantially increased the difficulty of execution.

Team management

Another fact that put us to the test was the simultaneous presence on site of several entities including direct suppliers of the hospital. This situation raised questions in terms of planning and work progress, communication, cost, deadline control and systematisation of the decision chain. The average daily number of construction workers was around 650.

The Solution

The multiplicity of questions that were raised demanded from our team several answers, not only in terms of engineering, but also in terms of management, cost control, and planning.

Top-down construction method

This system, which reverses the order of building the basement floors, was successfully used for the execution of the underground reinforced concrete structure because it was the only solution compatible with the constraints imposed by the existing infrastructure and the characteristics of the land, in addition to responding to ambitious construction planning. It’s a very demanding building technique, that involves heavy equipment means and constant geotechnical monitoring, but with the decisive advantage of minimizing the negative impacts on existing infrastructure.

Progress tracking methodology

It was one of the key success factors, considering the need to articulate the huge dispersion of resources and the high volume of information produced.

Shifts and routines were established as well as simplified methods of representing the progress of the design and the construction work, that allowed our teams to produce, in a timely manner and in a functional format, graphic representation matrices. The archaeological discoveries and its follow-up since the initial phase of the work raised a new challenge in the formulation of these routines for monitoring and managing the various activities.

The methodological solution adopted allowed all entities, designers, contractors, suppliers, and external service providers – to access concise and objective information that allowed them to establish and prioritize the actions to be taken, mitigating in real-time the potential impact of the changes made.

Cost control methodology

It was decisive in this project and proved to be the only way to guarantee the progress of the works without blocking the decision chain. For this, systematic “multi-team” appraisals and decision actions were stipulated, thus ensuring a permanent pace of presentations, analyses, and approvals of the various cost changes up to their budget accounting.

A solução metodológica seguida permitiu que todos os intervenientes – projetistas, empreiteiros, fornecedores e prestadores de serviços externos – acedessem a informação concisa e objetiva que lhes possibilitava estabelecer e priorizar as ações a desencadear, mitigando, em tempo real, o impacto potencial das alterações efetuadas.

Metodologia de controlo de custos

Foi determinante neste projeto e mostrou ser a única forma de garantir a evolução dos trabalhos sem bloquear a cadeia de decisão. Para isso, foram estipuladas ações sistemáticas de apreciação e decisão “multi-equipa”, assegurando-se, dessa forma, um ritmo permanente de apresentações, análises e aprovações das diversas alterações de custo até à sua contabilização orçamental.

The Result

As we overcame our challenge, through the implementation and sharing of good practices with all entities involved we helped our client to fully achieve their goals.

Rigor

Our intervention was essential in meeting the construction deadlines, in controlling costs, in managing the planning and articulation between all the entities involved and in implementing the demanding requirements of the project in terms of quality, safety and operability.

Value Creation

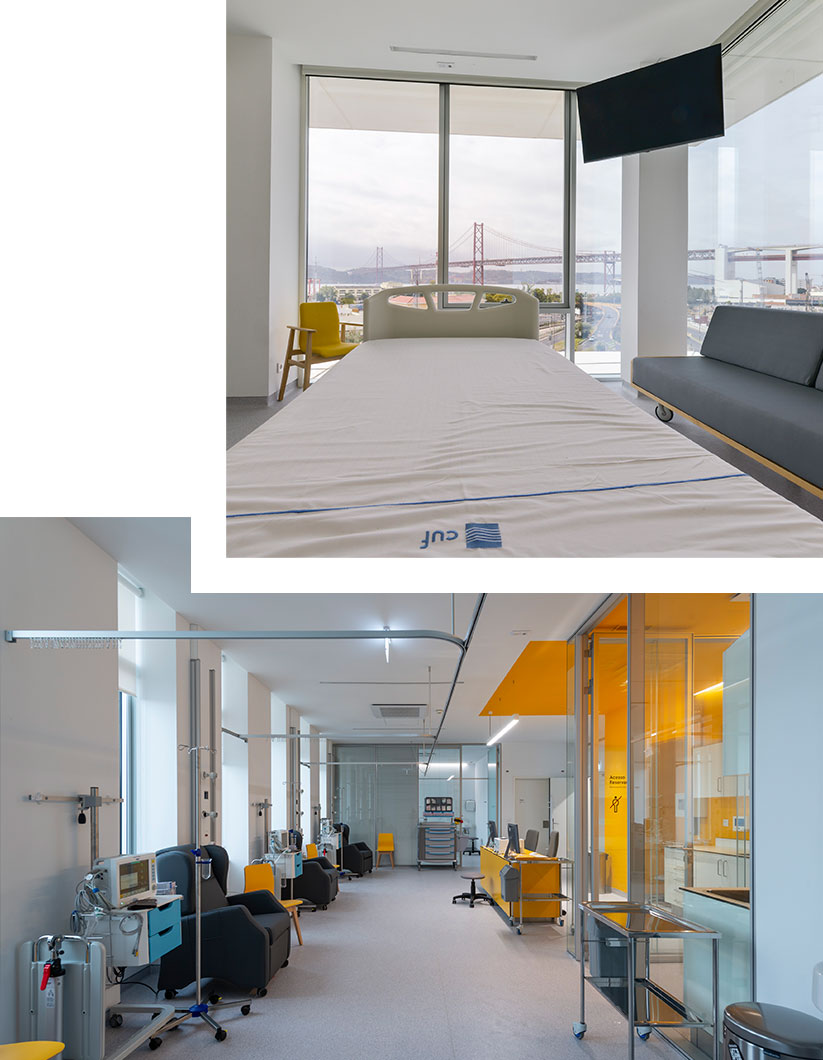

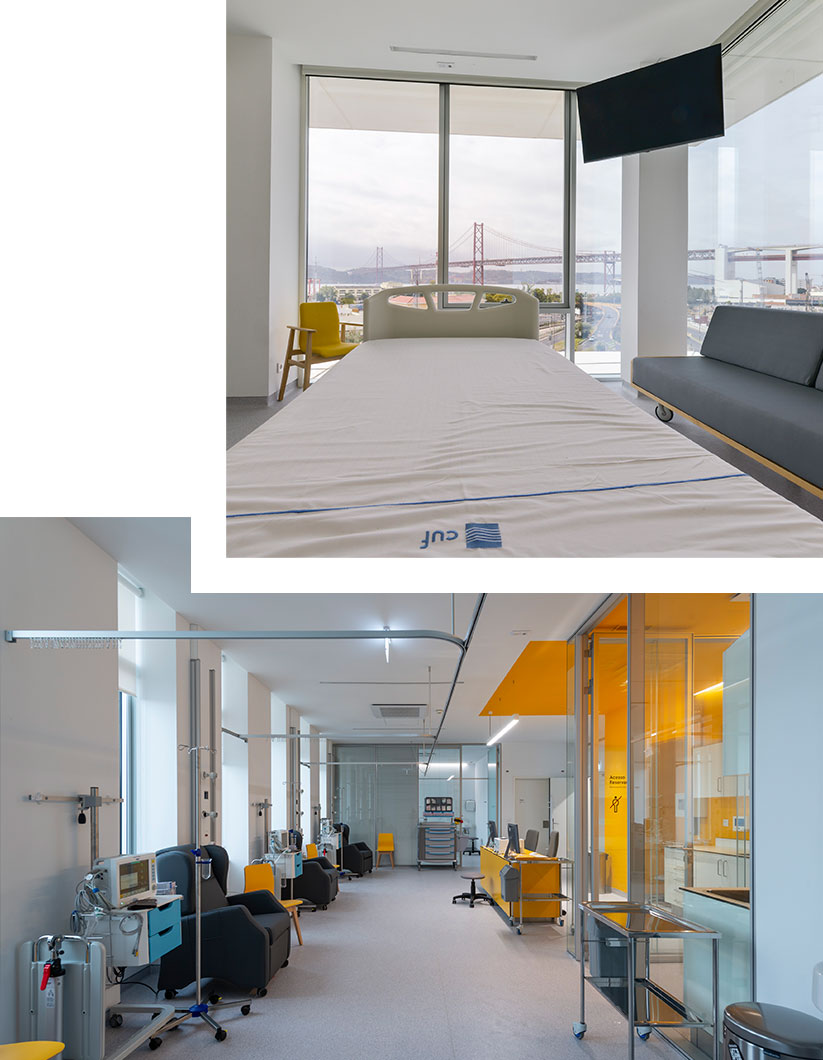

We managed to generate value throughout the process and contribute with our experience and professionalism to the success of this iconic project, which is characterized by being one of the most modern and advanced private health unit in Portugal.

Differentiation

The new CUF Tejo hospital stands out for its high differentiation, based on a modern physical and technological infrastructure that aims to prevent, diagnose and treat the diseases of the future, namely in the areas of oncology, neuroscience and cardiovascular.

Commitment to Sustainability

Contribution to environmental health is a commitment to the new hospital. For this, a set of solutions were adopted to make the building sustainable, with a focus on saving water resources and using a clean and renewable energy source.

In the heart of these measures were the creation of a reusable water distribution network and the installation of a solar energy system.

Energy efficiency and acoustic façades

The solution recommended for the façade was, in itself, a huge challenge. Architectural boldness was combined with the premise of maximizing prefabrication in addition to the use of energy-efficient acoustic materials. At the same time, fire safety regulations were complied with.

High seismic resistance structure

The structural solution adopted by the designer is based on a reinforced concrete structure with prestressed slabs in the largest spans, as well as wall and column systems that direct the vertical loads from the slabs to the foundations. This solution is responsible for providing the building with the necessary capacity to support the action, in safe conditions, of an earthquake that is of particular relevance in a hospital building.

Commitment to Sustainability

Contributing to environmental health is also a commitment of the new hospital. For this, a set of solutions was adopted to make the building more sustainable, which focus on saving water resources and using a clean and renewable energy source.

At the heart of these measures is the creation of a reusable water distribution network and the installation of a solar energy system.

Energy efficient and acoustic façades

The solution recommended for the façade was, in itself, a huge challenge. Architectural boldness was combined with the premise of maximising prefabrication in addition to the use of energy-efficient and acoustic materials. At the same time, fire safety regulations were complied with.

High seismic resistance structure

The structural solution determined by the designer is based on a reinforced concrete structure with prestressed slabs in the largest spans, as well as wall and column systems that direct the vertical loads from the pavements to the foundations. This solution is responsible for providing the building with the necessary capacity to support the action of an earthquake in safety, being of particular relevance in a hospital building.

Main technical solutions applied

Mixed steel and concrete structure with application of high-density intumescent treatment;

Large structural cantilevers with a combination of prestress concrete and the application of precambers;

Load tests of the structure for deformation control;

Introduction of water stop and anti-seismic expansion joints;

Aluminum façades of Technal MX series anodized in natural color, with high performance

Glass with high levels of thermal and acoustic insulation;

Application of prefabricated panels in GRC, large in size and with special quality control criteria in manufacturing and assembly;

Introduction of homologated vertical access systems for maintenance.

The main actors

CUF – Hospitais e Clínicas

Developer

Engexpor

Project and Construction Management

Teixeira Duarte – Engenharia e Construções

General Contractor

Frederico Valsassina Arquitetos

Architectural design

A2P Estudos e Projetos

Structural design

EACE Projecting Tomorrow

Electrical Design and Communications

Ductus Group

Hydraulic, Gas, Medicinal Gas

GET Gestão de Energia Térmica

HVAC design

Certiprojeto Arquitectos e Engenheiros Consultores

Acoustic

PROAP Estudos e Projetos de Arquitetura Paisagista

Landscape

RS, Raul Serafim & Associado

Fire safety design

KGEP

Technical Installations Monitoring